Horizon’s World-First 5MW AEM Electrolyser to Slash Green Hydrogen Costs by 2025

Singapore-based Horizon Fuel Cell Group sets the stage for cheaper, cleaner hydrogen production through a pioneering 5MW AEM electrolyser project in China, supporting decarbonisation of hard-to-abate industries.

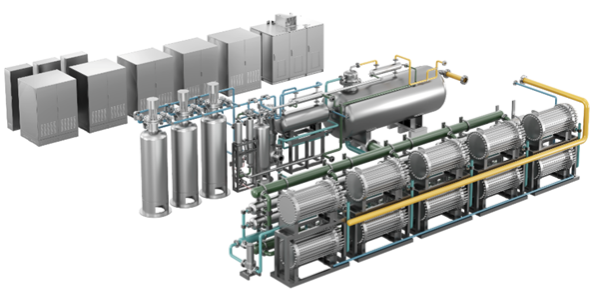

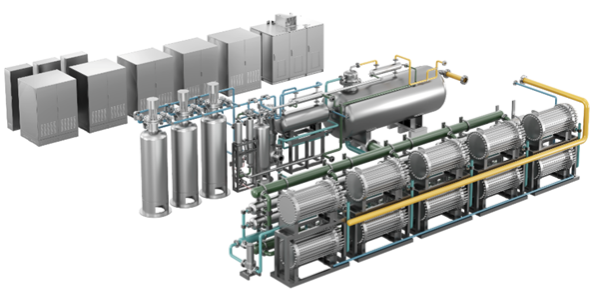

Horizon Fuel Cell Group is redefining the global green hydrogen landscape with the development of a world-first 5MW Anion Exchange Membrane (AEM) electrolyser, which will be deployed by late 2025. The revolutionary system is expected to deliver lower-cost green hydrogen at scale and will be first installed at Rockcheck Steel Group Co Ltd, a major Chinese steel enterprise based in Tianjin.

Through its electrolyser subsidiary HET Hydrogen, Horizon is addressing one of the most persistent challenges in the green hydrogen economy: affordability. The new 5MW AEM system is set to unlock cost-competitive green hydrogen for carbon-intensive sectors including steel production, green ammonia, methanol, and zero-emission transportation.

“We’re enabling a practical and scalable solution for sustainable hydrogen,” said a spokesperson at Horizon. “This is a key step toward making green hydrogen more accessible for industries struggling to decarbonise.”

The Tianjin deployment will form part of an integrated system that combines a 17MW building-integrated photovoltaic (BIPV) solar array with two 5MW AEM hydrogen production units. The hydrogen will be injected directly into Rockcheck’s gas pipeline, supplementing its blast furnace operations with clean fuel to reduce coal dependency and carbon emissions.

This partnership marks a breakthrough in hydrogen application for hydrogen-enriched smelting, a promising solution in greening steel—a sector notoriously difficult to decarbonise. The electrolyser is expected to go live by end-2025, providing both technological and environmental validation for AEM’s large-scale viability.

Why AEM Electrolysers Matter

Traditional alkaline electrolysers have long been a go-to for hydrogen production but suffer from higher electricity consumption and limitations in operational flexibility. Horizon’s modular AEM system addresses these issues head-on, offering:

- 10–20% reduction in power consumption compared to alkaline systems

- Improved cost efficiency with a lower Levelized Cost of Hydrogen (LCOH)

- Adaptability to intermittent power sources like solar and wind

Horizon anticipates that the widespread deployment of AEM units will drive capital costs down further, challenging the long-standing economic advantage of alkaline electrolysers.

Expanding Horizons: From Steel to Green Ammonia

Following its steel debut, Horizon has its sights set on green ammonia, which is gaining momentum as both a hydrogen carrier and low-carbon fuel for global shipping and power generation. Horizon is working with international collaborators to design a flexible green ammonia production scheme, positioning AEM electrolysis at the heart of emerging clean energy supply chains.

The AEM system’s compatibility with renewable sources makes it especially well-suited for use in regions abundant in solar and wind energy, enabling hydrogen production at costs as low as US$2 per kilogram—a milestone that brings green hydrogen within reach of mainstream adoption.

About Horizon Fuel Cell Group

Founded in 2003, Horizon Fuel Cell Group has been a pioneer in clean energy innovation. The company develops and deploys fuel cells and electrolysers across the hydrogen value chain, from power generation to mobility. It is known for displacing diesel in heavy-duty applications and remains committed to eliminating fossil fuels from industrial processes worldwide.

About Rockcheck Steel Group

Established in 1988 and headquartered in Tianjin, China, Rockcheck Steel Group employs over 10,000 people and ranks among China’s top 500 enterprises. With growing investments in environmental and social governance (ESG), Rockcheck is aligning its operations with global decarbonisation trends to modernise its infrastructure and improve its environmental footprint.